ball valve and plug valve

High quality

materials

Our plug taps are made of durable stainless steel or brass, which makes them particularly long-lasting and corrosion-resistant.

Precise

control

Thanks to their design, our plug valves enable precise regulation of the flow rate - essential for critical media in particular.

Versatile application possibilities

Our plug and ball valves are suitable for chemical processes as well as for food processing and mechanical engineering.

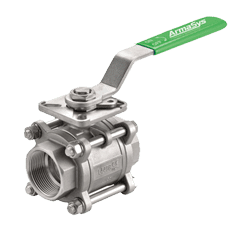

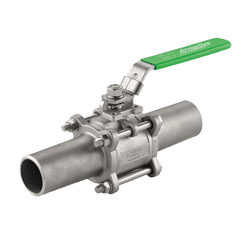

- Ball valve

- Spherical valve

- Plug valve

Ball and plug valves from germany for various applications

Main functions: For controlling, regulating and sealing media such as gases, vapors and liquids.

Functionality and advantages of ball and plug valves

In both types of valve, the moving parts – the ball in the ball valve and the plug in the plug valve – are crucial for controlling the medium. These parts are drilled through and the diameter of the hole determines the flow rate. By turning the ball or the plug, whether manually or automatically, the flow of the medium can be fully or partially regulated.

The advantage of this mode of operation is that it enables particularly precise regulation of flowing media.

Differences between plug and ball valves

The housing

The main difference lies in the housing design. Plug valves are characterized by a housing-free design without “dead space”, which means that no residues of the medium remain in the valve. This is particularly important when handling media containing solids or crystalline media, as this leads to a considerably longer service life in contrast to the ball valve.

Flow control

Ball valves or ball valves use a rotating ball with a hole that controls the flow. By turning the handle 90 degrees, the flow can be opened or closed, allowing for quick shut-off when required. In industries that need to conduct media at high temperatures – such as oil or gas – it is essential that these valves are absolutely tight and durable.

Plug valves, on the other hand, use a conical or cylindrical body that regulates the flow of the medium. By turning the plug base, the flow can be varied or completely interrupted, allowing for infinitely variable regulation. Plug valves are therefore more flexible and precise in their control.

Residue-free working with the plug tap - even in frosty conditions

The plug valve is the right choice, especially when using critical fluids where residue-free operation and durability are crucial. Residue-free tap housings can also ensure the transportation of media regardless of the outside temperature.

Ball and plug valves are durable, robust and low-maintenance

Due to their robust design and the small number of moving parts, ball and plug valves generally require little maintenance. Once they are installed, they often function reliably for years without the need for major maintenance. This saves you downtime and the tedious reworking of leaks.

We at ArmaSys are at your side with advice! Feel free to contact us by phone or e-mail – we can certainly do something for you.

We look forward to getting in touch with you!

- Bunsenstraße 5, 51647 Gummersbach

- 02261 5491325

- info@armasys.de

Our ball and plug valve range

| Ausführungen | Kugelhähne in ein‑, zwei- und dreiteiliger Bauform, Kompaktflansch- und Mehrwege-Kugelhähne |

| Werkstoff | Messing, Stahl, Edelstahl 1.4408, Sonderwerkstoffe |

| Nennweiten | DN 8 — 500 (weitere Nennweiten auf Anfrage) |

| Nenndruck | PN 10 — 100 (weitere Druckstufen auf Anfrage) |

| Anschluss | Flansch, Schweißende, Schweißmuffe, Gewinde |

| Varianten | E‑Antrieb, Pneumatikantrieb, Stellungsanzeige, Endschalter |

| Mehr Infos | Download Datenblatt » |