Efficiency and Speed Combined

Our pneumatic valves offer extremely fast switching times and precise control – perfect for applications where every second counts.

Robust and Low-Maintenance

Thanks to their simple, low-wear design, our valves are durable and virtually maintenance-free. Save time and costs in the long run!

Energy-Efficient and Cost-Saving

With low energy consumption and efficient use of compressed air, our valves offer the perfect balance between environmental friendliness and economic efficiency – ideal for reducing your operating costs.

- Compressed Air

- Pneumatic Valve

- Control Valve

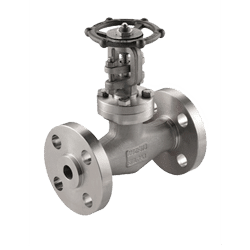

Pneumatic Valves – Efficient Control in Industry

Enhancing productivity with durable and cost-effective solutions for precise process control

What Are Pneumatic Valves?

Pneumatic valves are essential components in pneumatic control systems, used across industries such as automation, food processing, chemical manufacturing, and general production. They regulate airflow, control pressure, and thus enable the precise management of mechanical processes. In this article, we dive deeper into how they work, the different types available, and their significance for industrial applications.

How Do Pneumatic Valves Work?

Pneumatic valves operate by controlling the flow of compressed air, which triggers mechanical movements. This control can be manual, via mechanical actuation, or automatic, often through electronic control. These valves open, close, or throttle the airflow by altering the cross-section available for air within a system. The function of a valve heavily depends on its design and intended application.

The key components of a pneumatic valve include:

- Inlet and Outlet: Define how compressed air enters and exits the system.

- Control Elements: These can be levers, buttons, or magnetic actuators that open or close the valve.

- Seals: Prevent compressed air from leaking and ensure smooth operation.

Pneumatic valves often work together with other control components like air preparation units and cylinders to manage entire processes.

Types of Pneumatic Valves and Their Operating Principles

Choosing the right pneumatic valve depends on the specific system and application requirements. Here’s a closer look at the various types:

- Check Valves (One-Way Valves): Check valves prevent air from flowing back into a system, which is particularly important for safety and control applications. They allow airflow in only one direction and close automatically when backflow is detected. They are typically used to avoid pressure losses and protect equipment from harmful reverse effects.

- Pressure Regulators: Pressure regulators are crucial for maintaining a consistent working pressure within a pneumatic system. These valves reduce or limit the pressure and are essential for systems sensitive to pressure fluctuations. They can feature fixed or adjustable pressure limits and are commonly found in machine and production line pneumatic controls.

- Solenoid Valves (Electropneumatic Valves): These valves use an electromagnetic field to change the valve position. A solenoid valve is activated by an electrical pulse, allowing it to open or close almost instantaneously. This type of valve is widely used in automation systems requiring quick response times, such as industrial robotics or automated conveyor systems.

- Proportional Valves: Unlike other valves that are simply open or closed, proportional valves allow for gradual control of air pressure or volume. They are ideal for applications requiring fine-tuned control, such as in medical technology or high-tech manufacturing processes, where precise regulation of pressure and airflow is crucial.

Detailed Advantages of Pneumatic Valves

Pneumatic valves offer many benefits that distinguish them from other control systems like electric or hydraulic solutions:

- Robustness and Durability: Pneumatic valves are often designed for extremely harsh operating conditions. They are resistant to dust, moisture, and extreme temperatures, making them ideal for tough industrial environments. Their simple mechanical structure ensures a long service life with minimal maintenance.

- Fast Response Times: Pneumatic valves provide high switching speeds, critical for processes requiring immediate reactions. This is especially important in automotive production or the packaging industry, where efficiency and speed are closely linked.

- Easy Maintenance and Low Operating Costs: Due to their simple design, pneumatic valves are easy to maintain. With few moving parts, wear and tear are minimized. Furthermore, operating costs remain relatively low as compressed air is often readily available and inexpensive to produce in industrial settings.

- Safety Advantages: Compared to electrical or hydraulic systems, pneumatic systems are safer in explosion-prone environments. Since they do not generate sparks, pneumatic valves can be used in areas working with flammable substances, such as in chemical industries or refineries.

Application Scenarios and Industrial Importance of Pneumatic Valves

Pneumatic valves play a vital role in many industries. Here are some specific application examples:

- Automation and Robotics: In automation technology, pneumatic valves control the movements of grippers and robots. Their fast response capabilities allow precise positioning and movement in production lines.

- Food and Beverage Industry: Pneumatic valves control the dosing and distribution of liquids and gases. Due to high hygiene requirements, pneumatic systems are preferred because they are easy to clean and sterilize.

- Pharmaceutical and Chemical Industries: In these sectors, processes must be precisely controlled and monitored to ensure consistent product quality. Pneumatic valves regulate the flow of chemicals and other media here.

- Mechanical Engineering and Manufacturing: Machines and production lines use pneumatic valves to control movement sequences, such as lifting, lowering, or shifting workpieces. Their reliability contributes to machine efficiency and longevity.

Pneumatic valves are indispensable components in modern industry. They offer a reliable, efficient, and safe way to control pneumatic systems. Thanks to their versatility and ability to be precisely tailored to different applications, they play a key role in automation, mechanical engineering, and many other industries.

If you are looking for high-quality pneumatic valves to optimize your processes, we are happy to provide you with individual and comprehensive advice. Contact us today to find the right solution for your requirements.

We look forward to hearing from you!

- Bunsenstraße 5, 51647 Gummersbach

- 02261 5491325

- info@armasys.de

Our Product Range

| Types: | Shut-off valves, control valves, and regulating valves |

| Material: | GG-25, GGG-40, C 22.8/GS‑C 25, 1.4408/1.4571, 15Mo3, 13CrMo44, 10CrMo910, 1.4903 (P91) |

| Nominal Sizes: | DN 8 — 500 (other sizes available upon request) |

| Nominal Pressure: | PN 10 — 630 (other pressure ratings available upon request) |

| Connection Types: | Flange, butt weld end, socket weld, threaded connection |

| Additional Options: | Electric actuator, position indicator, limit switch |

| More Information: | Download Data Sheet » |